Biogas is produced by the microbial decomposition of substances under anoxic conditions. It consists of approx. 54 % methane and 40 % carbon dioxide (CO2).

CO2 is colorless, odorless and is produced, for example, during the combustion of carbon-containing materials, the production of fertilizers and fermentation.

What are the requirements to sell my liquid CO2?

Contaminants are a problem in the utilization of CO2 from biomethane. A European industrial standard has been created specifically for this purpose. This was initiated by the European Industrial Gases Association.

The standard (EIGA DOC 70/17) regulates limits for impurities in the ppm range, origins and verification. In addition, the Eiga standard requires food safety risk analyses and food safety management systems, which also include the fermentation of substrates. In accordance with the legal requirements, each supplier should implement a Hazard Analysis Critical Control Points (HACCP) system. This is a hazard analysis in which critical control points are identified ((EIGA Doc 70/17 (EUROPEAN INDUSTRIAL GASES ASSOCIATION AISBL)).

What are the marketing criteria for my liquid CO2 ?

- The composition >99.97 Vol.% CO2

- Food grade according to EIGA 70/17

- Pressure approx. 20 bar (g)

- Temperature approx. -30 °C

- Pressure dew point > -55°C

How does the CO2 processing and transport take place?

The CO2 is captured during biogas processing, purified and liquefied with a CO2 plant.

The liquefaction process requires a compressor, which compresses the CO2 to such an extent that it changes into the liquid state of aggregation.

The CO2 can then be delivered to industry in special tanker trucks for further use instead of being released unused into the atmosphere.

What is the financial benefit of CO2 capture and LCO2 production?

To make the sale of CO2 financially worthwhile, at least 2,500-5,000 t/a should be produced and attention should be paid to the market environment (information from market participants). If the purchase from a regional bulk buyer exists, prices up to 50 €/t can be achieved. It has to be taken into account that compared to the winter months, in the summer months there is a significantly higher demand for CO2 from large customers on the market. This is due to increased consumption of, for example, carbonated beverages, dry ice and refrigerants.

How are emissions savings achieved through carbon capture and reuse?

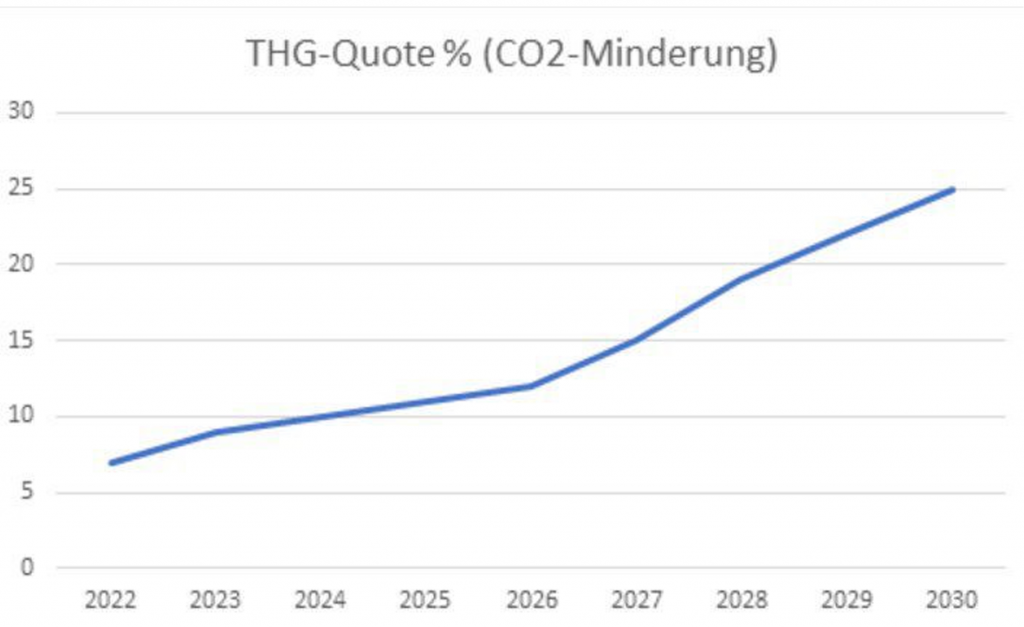

The CO2 reduction is referred to as the greenhouse gas reduction quota (GHG quota). Producers of fossil fuels are required by law to reduce their greenhouse gases. If they cannot achieve this to the required extent, they must pay penalties as compensation. This is shown as a percentage and explains the marketing of sustainable fuels in relation to the total volume (including fossil fuels). Currently, the GHG quota is 7% and is expected to increase within 8 years to 25% by 2030 (https://ibbk-biogas.com/thg-quote, 11.08.2022).

What is the role of the Renewable Energy Directive II (Red II)?

Which types of substrates are fed into the biogas plant play an important role in the remuneration. Care should be taken to ensure that not only NawaRo's are used, but advanced substrates such as manure/slurry. Whether it is a sustainable biofuel was defined in RED II.

Carbon Capture Utilization (CCU)/Carbon Capture Recycling (CCR) or Carbon Capture Storage (CCS) add a bonus to the GHG balance in the form of negative emissions. For example, the average GHG value of manure is -100 g CO2/ MJ. If CO2 liquefaction occurs, a further -30 to 50 g CO2/ MJ is credited. Here, an individual calculation of the savings is often useful.